MAS 20 shoes. The champions have already chosen them.

When you think you’ve developed the best shoe in rowing, you naturally want the best rowers in the world to be the first to test. So, that is why we turned to multiple Olympic champions, Martin and Valent Sinkovic, to try our new offering last May in Belgrade. The appreciation for the superior comfort of the shoes was apparent after only a couple of training sessions and the brothers went on to claim the first World Cup in the Men’s Doubles. A winning debut therefore for the brand-new Mas 20 shoe which have already been fitted to Filippi hulls leaving the Donoratico boatyard for numerous international destinations.

It was not easy to reach the final goal. The Mas 20, which replaces the original M.A.S. system launched in 2017, is the result of 30 years of experimentation and experience attained at racing venues around the world. We are proud of a product built upon innovation and ideation at one of the sport’s leading centres for forward-thinking and athlete-driven delivery. Even David Filippi, CEO of Filippi, engaged personally on this project in order to create something never seen before on the feet of our rowers and customers. We have taken this project to the next level, focusing above all on a lightweight comfort that makes all the difference in the world when you train for many hours a day and compete at the highest levels.

Shape design

The shape of the new Filippi shoes was developed in an asymmetric way that focuses on replicating the natural shape of the foot to ensure a perfect fit that enhances connection and improves comfort in the metatarsal area. With a squarer finish at the tip of the shoe, the shape will be wider and thus more flexible. As an example, the sole of the foot has been widened so that comfort is guaranteed in terms of trim even when it is subjected to stress in order to ensure a full load transmission.

The outer sole is ergonomic and has been lightened and softened in the central area to facilitate foot bending during the recovery phase without sacrificing the characteristic natural shape.

Upper and inner

The upper part of the shoe is still comprised of microfiber, colored in an exclusive shiny light blue with a metallic pigment. In addition to its exclusive appearance, this color reflects the sun's rays and decreases the heating of the shoe, which naturally improves breathability. The inner covering is made from sustainable recycled material; innovations at the interlock between the inner and outer sole include two waterproof, antibacterial non-woven fabric layers that will be matched with an extruded polyurethane core that adds lightness, and in particular, more flexibility.

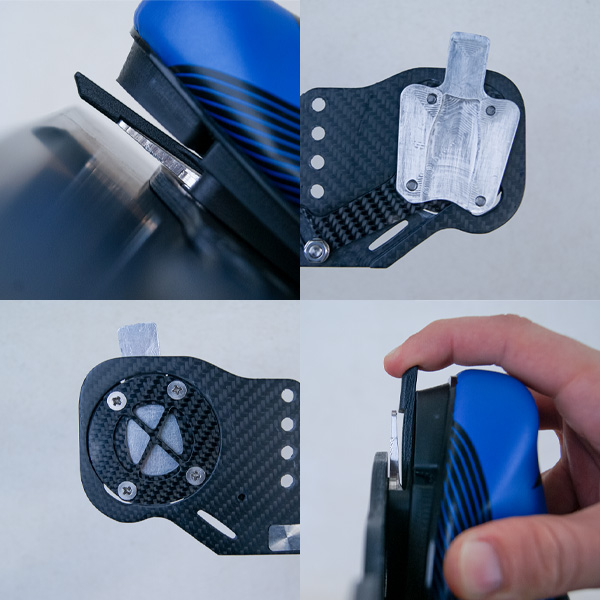

The rotors

The original three belts with Velcro horizontal fastening – which tends to loosen when in contact with water – have been replaced by two rotors developed by Filippi which harnesses the foot effectively on the stretcher, ensuring the athlete does not loose connection at varying points in the stroke. The rotors have mechanisms which allow for all possible millimetric movements through the tightening of a steel which goes far beyond the performance of a traditional Velcro belt. To release this wire in a safe manner, you must pull on the rotor with two fingers. For renewed safety, we also developed a release which opens the loop where the wire runs. Take note that a wire with 1.5 mm diameter has a tensile strength at 35 kg which guarantees an infinite life to the brand-new shoe tying system. The position of the rotors was extensively studied to ensure optimal foot wrapping, with a simple quick-release system patented by Filippi.

Inner sole

The inner sole has different areas of resistance to optimize thrust and comfort. Quite simply, there are no parallels in the rowing world.

It was built in E.V.A. (ethylene-vinyl acetate) and designed to avoid heel or tendon inflammation.

No more blisters on the heel

With Mas 20 we introduced some additional details that further differentiate our product from anything else on the market. The heel has been softened and ensures the absence of annoying blisters. The tongue of the shoe saves the instep from scrapes. It has been specifically designed to minimize the friction of the steel wire running on the rotor. The toecap ensures the seal of the shoe tip with longevity and beauty.

What is left of the original mas shoes?

We will leave unchanged a detail that no other rowing shoe manufacturer has so far been able to offer. Do you remember the semi-hidden plate inside the front of the sole? There are two – one on each side – located under the buttonhole. Up until now, these plates were made out of 316 stainless steel but, starting with the first supply of our new shoes, they will be repurposed in titanium for weight reasons (we can gain 20 grams for each pair of shoes) and for eliminating any form of oxidation.

This remarkable and perhaps little known buttonhole allows an additional two-centimeter range, up or down, to enable the athlete to obtain the optimal depth (the distance between the internal heel and the seat) of the heel once you have checked all the possibilities of adjusting the position of the shoes using the pins on the main platform. As a standard, the shoes are placed in a safe position in the lowest point of the buttonhole to avoid friction at the bottom of the cockpit. *

Thicknesses that improve performance

Different heel wedges for each sizing are supplied with the current shoe; they serve as a finishing touch to the shoe's profile and allow you to access the support of the carbon board rapidly. Additional wedges are available for sale and can be applied under the toe and in the back of the shoe sole, with three different inclinations to enhance the comfort and performance of the athlete.

Size chart

| EUR | 39 | 40 | 41 | 42 | 43 | 44 | 45 | 46 | 47 | 48 | 49 | 50 | 51 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| UK | 6.5 | 7 | 7 ½ | 8 | 8 ½ | 9 ½ | 10 ½ | 11.5 | 12 ½ | 13 ½ | 14 ½ | 15 ½ | 16 ½ |

| US | 7 | 7.5 | 8 | 8 ½ | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 |

| JP | 24.9 | 25.5 | 26.2 | 26.9 | 27.5 | 28.2 | 28.9 | 29.5 | 30.2 | 30.9 | 31.5 | 32.2 | 32.9 |

MAS 20 shoes use EUR sizing. Check the international size comparison chart to find the right size.

Quick-Release shoe: interface system

You can equip your boat with the optional Quick-Release shoe-plate system that is matched with the carbon plate and Filippi MAS 20 shoe.

The aluminium plate is fixed into the upper section of the carbon plate using countersunk screws. The nylon section (polyamide 12) is equipped with a “tongue” and goes directly on the sole of the shoe. A simple movement of the hands (or of the foot if you hook it up to a boat) will be enough to slide the nylon plate from bottom to top, until the tooth under the tongue hooks (clips) and locks the end of the interface.

The Quick-Release operation can be carried out manually whilst setting before going onto the water or directly in the boat.

Hygiene is maximised as the sole user of the shoe. In owning the shoe, you can also improve durability; for example, by letting them dry properly at the end of each training session.

A club purchasing multiple Quick-Release systems could even decide to fit a certain number of aluminium interfaces with the carbon plate of the footplate of their boats, allowing club users to purchase only the nylon interface.

Shop now

Take the proper care of your shoes

Take care of the MAS 20 shoes with the bioprotective anti-odor spray, specific for inner shoes. The long-lasting sanitary qualities allow you to maintain excellent hygiene levels in your rowing shoes.

Shop nowMore info

Video tutorial: winch opening and cable assembly

Can the Quick-Release system be mounted with other rowing shoes and/or boats?

Yes, it can also easily be used in combination with other shoe brands and boat manufacturers as long as the plate has four fixing holes per shoe.

Does the Quick-Release system go on all Filippi plates and footstretchers?

Yes, it does.

* In exceptional cases (i.e., for very large shoes), fixing the shoes according to the required depth could cause the heel to be too close to the bottom of the hull, preventing the athlete from moving the way they’d ideally like to. In this case, the main benefit is to be able to move the shoes up to two centimeters and with millimetric excursions, as long as you do not go too far beyond the end of the platform. To move the shoe, simply use a screwdriver to loosen the 5x10 screws that secure the shoes to the footplate, then move it in the desired direction before tightening the screws again.